Going to the hardware store so often that you're both "seeing red" and "in the red" on your project?

Let's start by saying that I'm not going to whine about any stores. Their business models ultimately provide goods with various logistical and economic challenges that most people are blissfully unaware of. It'd be hypocritical of me to rail against the big chains because I'm certainly no stranger to excessive hardware store visits.

That said, I'm also all-too-familiar with the long-term costs associated with repeated shopping trips and not all of them are "necessary". Whenever you find yourself grabbing the car keys to head off to grab something, it's worth stopping for a moment and consider "what can I do to avoid doing this?".

Why and how did I get to this disturbing tendency to shop first and think later?

I think it sneaks up on you. At first glance, buying stuff you've run out of makes sense. However, do it long enough... and I think I became resigned to the fact that regularly buying stuff just because my initial plans "hit a snag" is an inevitable part of most DIY projects. But I now kick myself for not questioning it sooner....

I get it, we all get wrapped up in life dramas, our internal understanding of the project, the design, the pressure of "when and how will I ever get this done?" and the ever possible, "Oh, I thought I had some of those laying about..." (as you find an empty packet and find nothing but sawdust in the bottom). All of this can blind the humble DIYer from alterative ideas... especially if you're like me, and you're conditioned to "follow the recipe" faithfully and perhaps... unquestioningly.

Of course, it's a bit sad when I was the one making the design in the first place. Hehe. If this sounds anything like you, then you are certainly not alone. :-)

Stop and think for a moment... what's the real problem here?

Here's a little "Ham's real-life story" for you:

I was working on installing some door latches just yesterday (at least, from the time of writing) and I had a solid notion of what that involved. Build a mount for four bolts by drilling holes into some scrap of wood, then shoving the thread through the drilled holes in the wood so they ended up sticking out, epoxy glue the countersunk heads into place, and bolt the spring-loaded latch to the four bolts using nuts.

Sounds easy enough...

However, when I did my dry fit (assembled it all without glue) I realised that holes on the latch were 5mm in diameter, and I had run out of M5 (5mm) bolts of suitable length.

Time to run to the store, right?

If I had longer 5mm bolts, I could have cut them down with a hack saw... but I didn't have any 5mm bolts whatsoever.

So now do I need to go to the store?

Actually, I checked my collection of fasteners and found that had some 6mm bolts and nuts, so I just drilled the holes a little bigger in the latch mechanism and mount. Voila, shopping trip successfully avoided. So not only did I avoid buying bolts, I ended up with a stronger construction due to using the bigger bolts and trivial amount of material removed by drilling larger holes.

Of course, you have to assess the feasibility of each possible "solution" on a case-by-case basis, and there are definitely times when one particular "solution".... is more complex, more costly, more problematic, and more hazardous to do. Keep safety in mind both with the DIYing stage and later use of the finished project.

Interesting thought... "Are overly complex solutions always bad?"

You might do that if a complex stop-gap measure is enough and that's your only option. Sometimes, complexity makes a project safer, easier to use, or more versatile. But that's not what I'm focusing on here in this article, since....

Fortunately, things are rarely that bad in the world of DIY! Saving time and money by coming up with creative solutions is absolutely possible in many situations.

Now, I've alluded to this in my other "DIY on a budget" articles.

- Why buy blades and drill bits if you can sharpen them?

- Why buy wood when pallets are given away for free?

- Why buy an expensive tool when a jig can help you do "that stuff" with the tools you already have?

- Why buy a jig if you can slap it together from the creative use of scrap wood?

The important word there.... is creative! But that also involves both mental and physical effort.

If that doesn't scare you off, it's amazing what you can do with a little inspiration and creativity. That said, sometimes throwing money at the problem (even at a reduced rate like buying stuff second hand or renting) can be easier too. So obviously, you need to pick your battles, plan, and just "have a go".

DIY creativity is not limited to avoiding buying tools and materials to save money, it's also about finding ways to:

- Use materials that would otherwise be thrown out, or clutter your workshop, by gluing some scrap bits together and sanding/painting it... or finding an innovative use for the bits you already have.

- Problem solving makes you more versatile, more capable, and better able to handle challenging conditions. which makes you a more versatile/flexible/capable DIYer overall, particularly in challenging conditions.

- Repair, instead of thoughtlessly replacing things helps you to understand maintenance processes. It goes beyond simply "making stuff" in the cheapest/easiest ways, because there are different/additional challenges in the disassembly, modification, and reassembly of premade projects. This certainly encouraged a more in-depth consideration of future needs, potential issues, and ease of modifications in my design and building processes. (Why glue stuff together if you may need to dismantle things and screws are enough?)

- Go back to basics: Master basic hand tools, which allows you to work without power, or late into the night without bothering people. Interestingly, despite being somewhat counter-intuitive, in many cases, hand tools can be just as fast (or even faster) as using power tools which usually require setting up before use. Or alternatively, "Going high tech".... which leads me to:

Means to make things "in house" may ultimately save you a fortune.

This isn't for everyone, because there's always going to be a learning curve, but a $350 printer + $100 worth of filament, can save you a lot more than $450 if used intelligently. The local hardware store charged me $35 for a single dust extraction adaptor for my shop vac. My dust system needed 6 of them ($210) I can now download a design from one of several model repositories online, and then print them as many times as I need for under $5 each. A saving of over $150 compared to store prices.

Learn to create your own designs and these machines can not only pay themselves off, but make you a lot of money as a "side-hustle" or even career. Just make sure you perform routine maintenance on your gear and learn to use it properly. They follow instructions religiously and don't care if it's what you intended or not. :~)

Pre-emptive problem solving when buying tools can save you as much money as using them.

In some ways many folks with cordless tools are forced to standardise to one brand because it saves buying several different styles of batteries and chargers. Sure, it has both pros and cons, but we can apply this concept to other areas of the workshop.

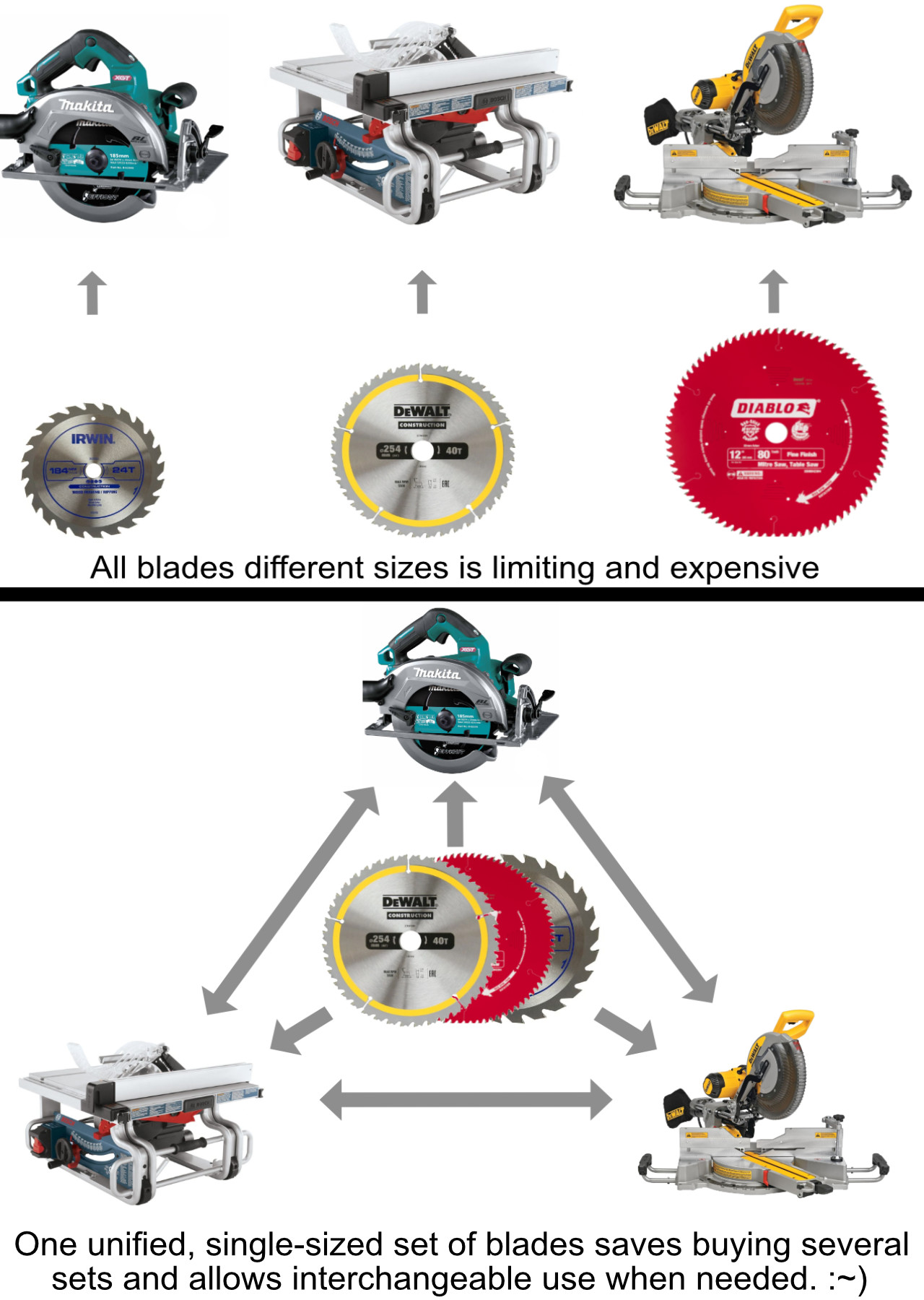

In this case, complimentary/standardised tooling is about choosing tools specifically so that consumables and accessories can be used interchangeably between the similar tools for whenever you need to.

For example:

If the table saw had a 254mm (10") blade, the mitre saw a 304.8mm (12") blade, and the circular saw a 184mm (7.25") you can't swap them around. So you need three separate blade sets to handle various tasks. However, if they all used a 10" blade (which is a good common size across all three saw types) not only can you save money by purchasing the significantly cheaper 10" blades instead of 12" blades for your mitre saw with little practical use penalty (although that depends on your typical use) you can get by with just one set of blades. This way, you're less likley to buy the wrong size, you don't go "ah now I can't do my rip or cross cuts.... until I get to the shops again". If you get really stuck, you can always take the blade you need out of the mitre saw and drop it in your table saw, or from circular saw and put it wherever it'll help... you get the idea.

Even if the tools have different arbors (axle diameters) spacer rings/bushings can easily solve the problem. Just make sure you have the right sized rings/bushings to get to the size of both the axles, and the hole in the blades. (Ok you might need a set of spacer rings, but many blades include a few options).

But why stop there?

A little example...

Now machines break down... and if you're a farmer... it's likely that you're out of town. Instead of buying engines in a piecemeal manner, it actually makes sense to buy several of the same engine (say a Honda GX200), so they're all the same, they run with the one single set of consumables, same attachments, same fuel, same spark plugs. If you can afford to, consider buying a whole spare engine so that you can get one repaired as the spare does the work. This saves a tonne of time and money over years, and can make or break a farm in tough years.

Back to a small workshop...

Standardising attachments for say... a dust extractor makes life a lot easier too. So make sure your tools all have a similar port available, or add an attachment that allows you to work that way.

Going beyond circular saw blades for a moment...

If you have a a planer and jointer with helical heads, getting a set of common blades again saves time and money. The combination devices (ones with both jointing and thickness planing capability) often share such consumables, and save precious work space if you have to have two large stationary tools. That said.... honestly, it's pretty hard to unify different types of machines (a band saw and a drum sander) beyond the dust port... so if you have tools that share a similar function, look for these oppotunities where you can.

Anyway, I hope you consider this when you're choosing your next big purchase. It'll help! I swap blades between my table saw and mitre saw all the time. The fact that I keep getting free 7.25" circular saws in my redemptions is the only reason I haven't standardised that yet. :~)